-

Email: cnc88max@dingtalk.com

Email: cnc88max@dingtalk.com

-

Phone: +86-18021988367

Phone: +86-18021988367

- DESCRIPTION

- TECHNICAL PARAMETERS

- CONTACT US

-

0

Establish In

Establish In

-

0+

Building Area

Building Area

-

0+

Employees

Employees

-

0+

Export Country

Export Country

-

Industry News

Industry News -

Industry News

Industry News -

Industry News

Industry News -

Industry News

Industry News -

Industry News

Industry News -

Industry News

Industry News

When Turn-Mill Composite Actually Beats “Lathe + Mill”

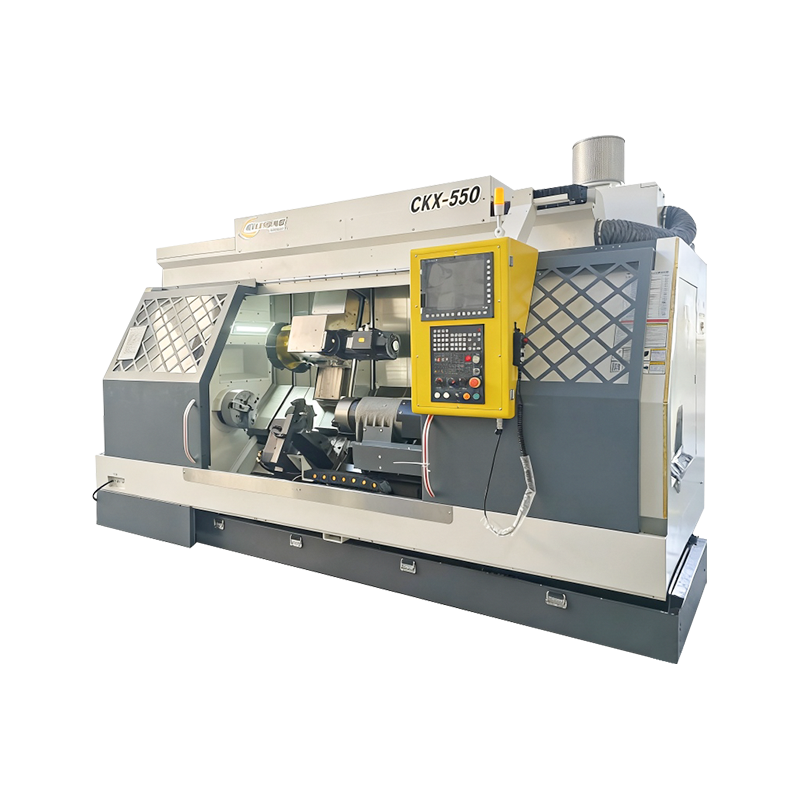

A efficient machining turn-mill composite machine tool shows its advantage when a part needs multiple datum conversions (turning, milling, drilling, tapping, off-center features, angled holes) and the tolerance chain is tight. If you move a part between machines, every re-clamp adds error, plus the “hidden cost” of setup time and in-process inspection.

- Parts with coaxial + prismatic features: one clamping preserves concentricity and true position better.

- Medium batches with frequent changeovers: fewer fixtures and fewer offsets reduce non-cutting time.

- High value parts: scrap risk drops when the process is consolidated and monitored in one control system.

In our own line, we keep R&D and process improvement focused on one thing—turn-mill composite technology—so the iteration speed stays high and the platform becomes more mature with lower failure rates over time.

Datum Strategy: How to Protect Concentricity and True Position

On a turn-mill composite, your biggest accuracy gain often comes from datum planning rather than chasing micron-level specs. The goal is to keep functional surfaces referenced to a stable datum set across all operations.

Practical rules that reduce tolerance stack-up

- Turn the primary locating diameter and face first, then mill features that reference those surfaces.

- Use probing to “close the loop” after roughing, before finishing critical patterns.

- Avoid re-clamping unless necessary; if required, re-establish datum using in-spindle probe and dedicated locating features.

- Keep toolpaths consistent with your GD&T: finish the surfaces that drive the tolerance last to minimize deformation effects.

A common buyer mistake is “spec shopping” while ignoring datum discipline. In real production, one-setup datum continuity is usually the bigger lever.

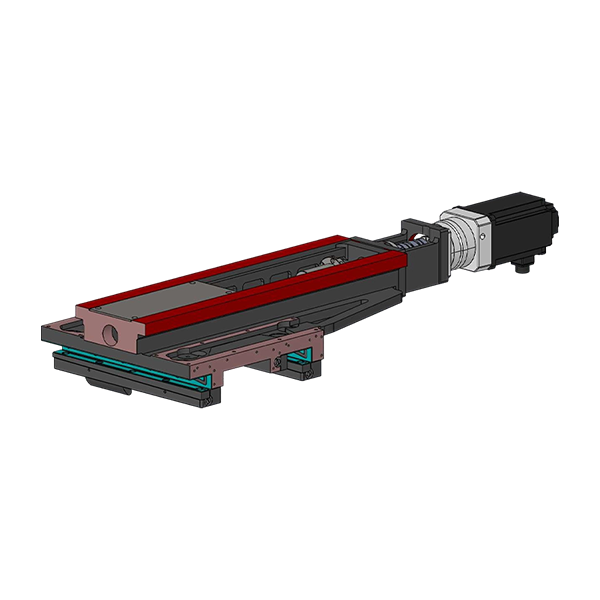

B-Axis vs. Fixed Milling: What You Gain, What You Must Control

Adding a B-axis (or equivalent multi-axis milling capability) expands the feature envelope—angled faces, compound holes, freeform milling—without secondary setups. The tradeoff is that calibration and process discipline matter more.

| Capability | Best-fit applications | Key control point |

|---|---|---|

| Fixed-angle milling | Slots, flats, bolt circles | Spindle-to-work offset stability |

| B-axis / multi-axis milling | Angled holes, impellers, complex faces | Rotary axis calibration + probe verification |

If your parts are mostly 2.5D milling on turned stock, you may not need full multi-axis. But if you do, ensure the builder has a proven calibration method and supports verification routines—this is where an R&D-focused manufacturer can make the ownership experience smoother.

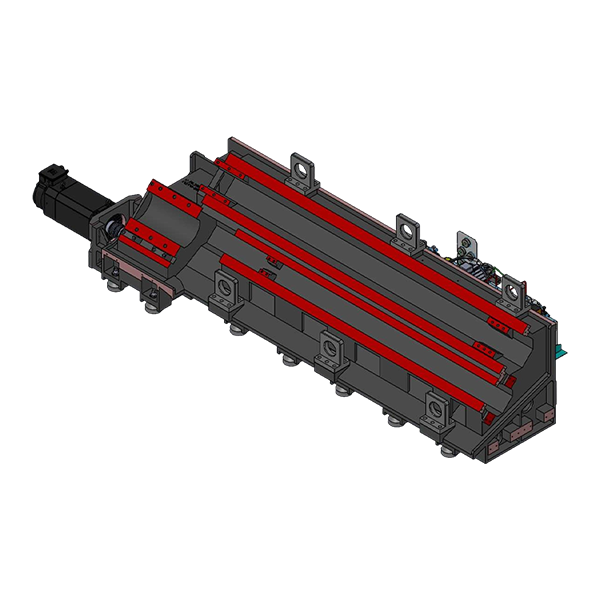

Chip Control: The Hidden Determinant of Uptime in Composite Machining

Turn-mill composite cutting creates mixed chip types: long turning chips, broken milling chips, and stringy drilling chips. Chip evacuation is not cosmetic—it impacts surface finish, tool life, spindle load alarms, and even axis wear if chips recirculate.

What to engineer into the process

- Use chip-breaker geometries for turning; do not “force” chip breaking by over-feeding if it harms finish.

- Sequence operations so heavy turning doesn’t bury delicate milling features under chips.

- High-pressure coolant is most valuable for deep drilling, parting, and gummy materials.

- Watch for chip packing around the sub-spindle/secondary holding area; it’s a frequent source of unexpected downtime.

When evaluating machines, ask about chip evacuation design and serviceability. In real shops, chip stability often equals production stability.

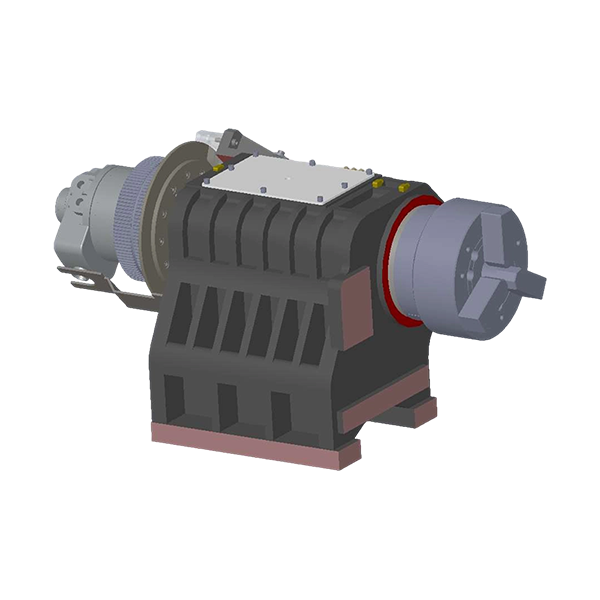

Thermal Behavior: Why “Morning Good, Afternoon Bad” Happens

Composite machines concentrate more heat sources in one enclosure: main spindle, milling spindle, servos, ballscrews, and often a second spindle. As temperature drifts, so do tool center points and spindle growth—especially noticeable on long parts or deep bores.

Shop-floor tactics to stabilize accuracy

- Warm up using representative spindle speeds and axis motion, not just idle running.

- Finish critical diameters/bores after the machine reaches a stable thermal state.

- Use probing to compensate: measure a reference feature and correct offsets before final passes.

- If your tolerance is tight, standardize coolant temperature and keep enclosure doors closed during finishing.

The practical takeaway: repeatability comes from thermal consistency more than one-time geometry checks.

Tool Management: How to Prevent Collision and Reduce Non-Cutting Time

Because turning and milling tool systems share the same working envelope, tool management is both a productivity lever and a safety requirement. Collisions often come from overlooked tool length changes, poorly set work offsets, or mixed coordinate conventions between turning and milling cycles.

Process controls worth standardizing

- Maintain a efficient machining turn-mill composite machine tool library with verified gauge lengths and stick-out limits; lock edits behind permissions.

- Use tool presetter + in-machine measurement where possible to catch offsets drift early.

- Standardize safe planes for both turning and milling operations; avoid “custom safe planes” per programmer.

- Introduce a dry-run protocol for new programs: reduced feed, single block, and collision-check focus near chuck/jaws.

This is also why we keep spare parts and technical support dedicated to one machine type: fast response is most meaningful when you’re trying to protect uptime.

Workholding Choices That Make or Break Composite Machining

In turn-mill composite work, the chuck and jaws do more than hold— they define the datum, influence roundness, and determine whether transfer operations are stable. Over-clamping can deform thin-walled parts; under-clamping causes micro-slip that ruins surface finish and positional accuracy.

Common scenarios and best practices

- Thin tubes / rings: use soft jaws bored at the same clamping force used in production; finish critical IDs after stress is stabilized.

- Long shafts: use tailstock/support or steady solutions; prioritize vibration control before increasing speed.

- Transfer to sub-spindle: add a locating feature (pilot/shoulder) so the second grip references a known surface.

- High torque milling on turned stock: verify jaw serration and contact pattern; poor contact is a silent source of chatter.

If you want a quick evaluation: improve workholding first, then tune parameters—workholding changes can deliver immediate yield improvement.

English

English 中文简体

中文简体 русский

русский 日本語

日本語